| |

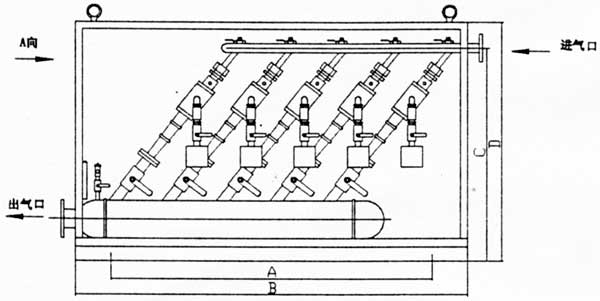

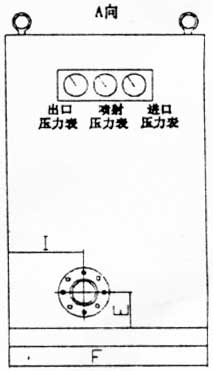

Venturi Injection Mixer makes use of the pressure of LPG, which is injected in a high speed via an ultrasonic nozzle.Therefore, the chamber induction is under negative pressure and injected with air from outside. After the air and LPG are mixed up with each other well in the venturitube, the mixture then is sent out. The power of the equipment is automatically controlled by the pressure in the tube. Since the air is injected because of the negative pressure, the injection pressure of LPG should be at least 3kgf/c©O.The air-to-fuel ratio can also be adjusted within a certain range. But one problem is the pressure of the gas mixture is a little bit low (usually under 0.5kgf/c©O) when it is transmitted. If under high pressure, pressurized air out of the chamber induction is required. This is what we usually name as Venturi Booster Mixer, which can improve the transmission pressure considerably and satisfy the needs of long-distance transportation.

Since single-tube's mixing capacity of Venturi Injection Mixer is limited, during the process of application, there may be some problems in matching the output of the gas mixture with the using quantity. Following ways can solve these problems:

1.Installing a surge tank.

2.Applying multi-tube mixer and matching the output and using quantity according to the frequency of tube pressure's auto-powering the venturi.

In the gas mixture system, signals of the calorimeter and the analyser of oxygen quantity are usually led into the control system so that the air-to-fuel ratio can be acquired at any time. Once it exceeds a certain extent, the mixer will power off automatically to ensure that the system is running in safety.

|

|