| |

|

| |

|

| |

| |

|

|

| |

LPG has been enjoying increasingly wide popularity because of its easy-to-obtain,convenient-to-transport,high calorific value and environmental friendliness.

During the process of application, it often needs to be intermingled with a certain amount of air according to the practical conditions.The gas mixture thus can be interchanged with natural gas and coal gas, and can also meet the needs of long-distance transportation under medium pressure in some relatively cold areas. In addition, some gases of low caloricity can be increased in calorific power if mixed with LPG.

On the whole, gas mixture has been widely used in daily practical projects.The mixture ratio should be at least 1.5 times of the upper limit of explosion.

|

|

| |

|

|

|

| |

|

| |

|

| |

|

| |

| |

|

|

| |

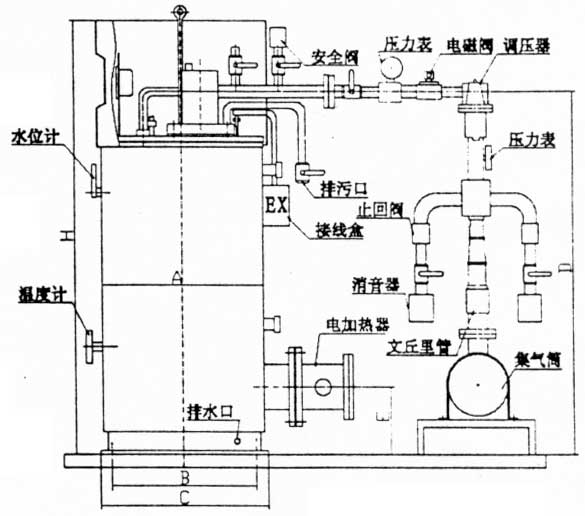

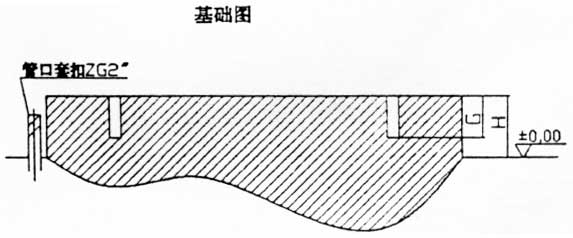

Vaporization /mist -Body machine, a kind of compact lines equipped with the vaporizer and Venturi mixer, enormously reduces the investment in project with compound air mixing in the cylinder combination. As for the perfect combination of the practicability and economy, it applies to some relatively small-scale units. Provided the compounding air only, such facilities can be used in the station room rebuilding. Adding about 15% air to the liquefied gas can cut the operating cost at a large margin, which is then considered as a most ideal way.

|

|

| |

|

|

|

| |

|

| |

| |

|

|

| |

(1) Steady mixing condition, low cost

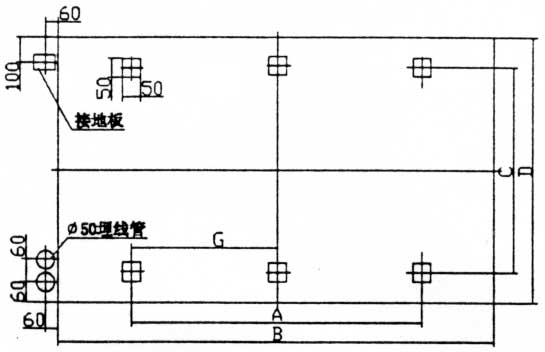

(2) Silencer, filtering, echo-avoiding are set up at air inlet

(3) Mixing among the cylinder combination reduces cost

(4) High pressure at the gas outlet fulfills the long-distant transportation

|

|

| |

|

|

|

| |

|

| |

| |

|

|

| |

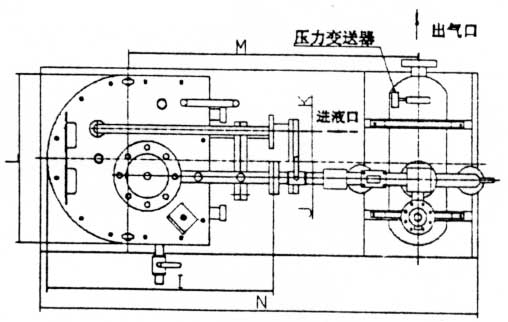

(1) Mode of mixing: Venturi Injection/ OVM(Orbiting Velocity Meter)

(2) Proportion of mixing: 9:1~1:4.5

(3) Pressure of liquefied gas jet: 0.3~0.5Mpa

(4)Pressure at the liquefied gas outlet: °‹0.6kgf/cm2

|

|

| |

|

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|