| |

|

|

| |

|

| |

| ¡¡Fuel Gas Emergency Shut-off Solenoid Valve |

|

| |

| |

|

|

| |

Such SV series with a manual restart and a shut driven by galvanic pulsatory current also gets auto-controlled anti-explosion sets of casting kind. With the help of some excellent professional software, it is mainly designed for the safety, which the fuel gas emergency shut-off in the low-pressure tube acquires in the urban area. Employed by mature and precise design, It has passed many reliable experiments and tests, which are definitely prior to other products of the same kind, so that high quality and profession then can be guaranteed.

|

|

| |

|

|

|

| |

|

| |

| |

|

|

| |

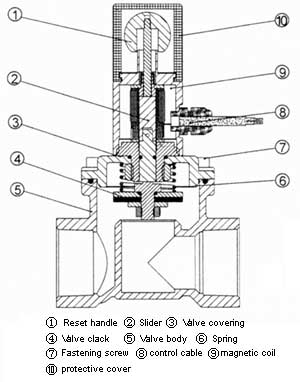

Fully taking advantage of the interaction between electromagnetic force and spring force;

High efficiency by taking use of magnetic circuit and accurate processing technology;

Shut by the drive of low voltage galvanic pulsatory current and restart by manual & sustained by auto-control;

Good consistence and reliability;

Mass production to satisfy the market;

|

|

| |

|

|

|

| |

|

| |

|

| |

|

| |

| |

|

|

| |

¡ñ Casting Seals & Anti-explosion: Permitting no electrical spark makes no hidden danger or source of detonation

¡ñ Way of start: Manual reset, manhandle the start on site; according with the feature of accident disposal

¡ñ Way of shut: Driven by low voltage galvanic pulsatory current

¡ñ Shutting rate: Within 1 second

¡ñ Shutting control: Low exhaustibility when driving, supporting the fire control working, according with fire controlling code (matching the controller)

Signal output: Output the feedback signal of the start/shut on the control line of two shut valves;

¡ñ Sustain ways: Auto-controlling without electricity

Manual shut: Acts as the brake valve when the electricity is powered off

¡ñ Shut with strong shock: Regulating of the confining force to automatically shut off when encountered with harmful shock

¡ñ Tight seal: Multichamber, precise processing, excellent air-tightness and security, NBR/FKM rubber designed for different gas, ageing resistance within 10 years in the urban areas;

¡ñ Reliable performance: 20,000 fault-free records testified by actuator

|

|

| |

|

|

|

| |

|

| |

| |

|

|

| |

¡ñ Applicable material: Natural gas, liquefied gas, manufactured gas

¡ñ Seal material: NBP rubber, FKM rubber¡¯

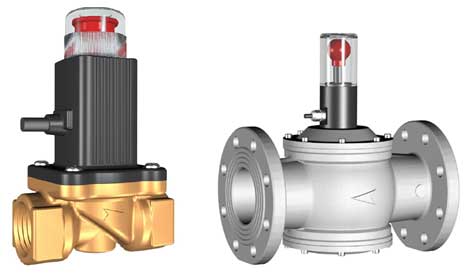

¡ñ Body material: brass alloy, Aluminum alloy

¡ñ Operating temperature: -10oC ~ 60oC

¡ñ MAX operating pressure: 0.5bar¡¢1bar

(1bar=0.1Mpa=14.51PS)

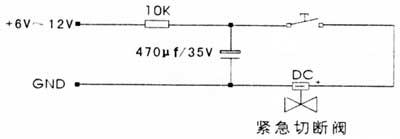

¡ñ Power Supply(Driving voltage): DC6v¡¢9v¡¢12v¡¢24v

¡ñ Power On Hours:¡Ü30seconds

¡ñ Closing time: ¡Ü1seconds

¡ñ Anti-explosion Signal: Exm¢òT4, Exm¢òT6

¡ñ Degree of Protection: IP54 (protective cover is acquired)

|

|

| |

|

|

|

| |

|

| |

| |

|

|

| |

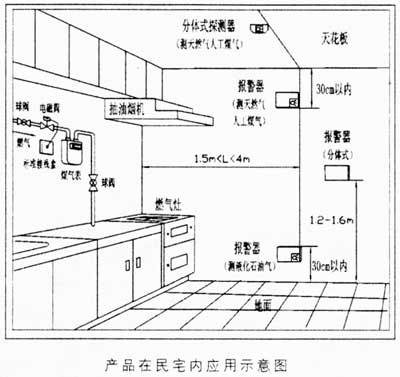

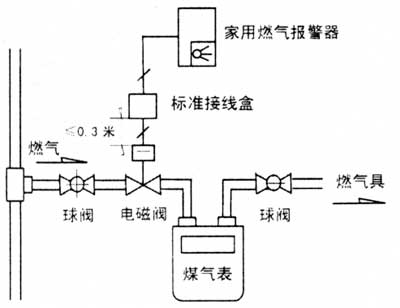

¡ñ Household Style

AFO1B-DN15 and AFO1B-DN20 are mainly applied in the gas-consuming locations of residences, such as high-rise residential buildings and intelligent blocks. In general, they are designed to integrate with household gas monitor and usually installed on the gas pipe, between indoor gas meter and globe valve, which is very convenient for gas companies' installation and supervision. Such products, controlling circuit by shutting off the valve, are simple to operate, fail-safe, cost-effective and easy to be incorporated with any kind of monitors of alarm apparatuses.

|

|

| |

|

|

|

| |

|

| |

|

| |

|

| |

|

| |

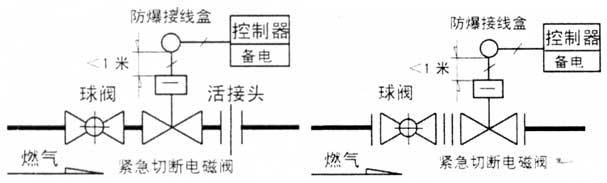

| ¡¡Commercial/Industrial Style |

|

| |

| |

|

|

| |

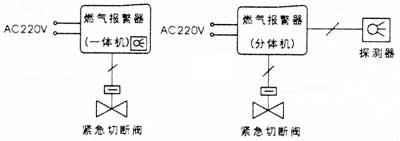

AFO1B-DN25~AFO1B-DN100 are mainly applied on the low pressure gas pipes of commercial and industrial locations with normative and standard requirements, such as kitchens in public buildings, induction mains, gas boiler rooms, direct-fired generator rooms, measuring chambers, equipment floor, gas-consuming areas, gas stations and so forth. Such kind of valve is primarily used integrating with industrial gas alarm, fire-alarm system or other safety control system to prevent gas leakage and the consequent fire and explosion accidents by emergently shutting off the gas supply. For the sake of safety and in terms of the standards of fire protection, valve control should have the capacity of storing electricity so as to fulfill the requirements when emergency shut-off is necessitous. Therefore, this company has specially designed a kind of valve control and control module with high performance and the capacity of storing electricity to satisfy professional consumers' needs.

|

|

| |

|

|

|

| |

| |

|

|

| |

¡ï Attention: The process of design, installation and supervision must be in the charge of gas pipe units or companies with professional qualifications.

|

|

| |

|

|

|

| |

|

| |

|

Installation Schematics |

| |

| ¡¡Commercial/Industrial Style |

|

| |

|

Schematics for products with connection of

inner-pipe thread |

Schematics for products with flange connection |

|

| |

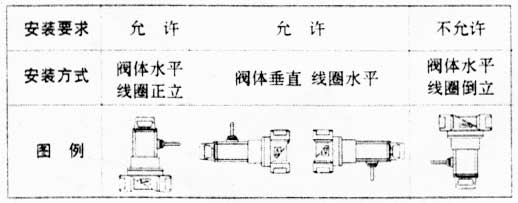

| ¡¡Installation Requirements |

|

| |

| |

|

|

| |

1. The valve should be fixed in accordance with the direction of air current indicated on the valve body, and the coil of valve body can be installed horizontally or vertically, but not upside-down.

Position requirements for installing on the pipe:

|

|

| |

|

|

|

| |

|

| |

| |

|

|

| |

2. Effective measures should be taken to prevent sundries from doing damage to the hermetical material in the valve when cleaning the inside of the pipe.

3. When shutting off the valve dynamoelectrically, incorrect connection of electrical source, such as false polarity connection, false voltage loading and long-time electrification, should be avoided by all means lest the electromagnetic coil be damaged.

4. The pressure of the pipe can be tested only if the valve is open.

5. If installed outdors, the valve should be fitted with guards against rain and snow, meanwhile, it should be used correctly within the range of the adaptive temprature.

6. The installation units should possess relevant qualifications and fix the valve in terms of the construction norms.

|

|

| |

|

|

|

| |

| |

|

|

| |

¡ï Warning: Any kinds of damage, losses and accidents due to unadvisable safekeeping, arbitrary disassembly and improper usage are not in the range of our company's responsibilities.

|

|

| |

|

|

|

| |

| ¡¡Requirements for cable distribution |

|

| |

| |

|

|

| |

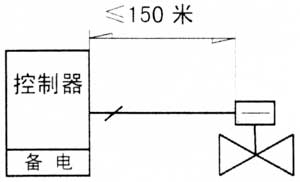

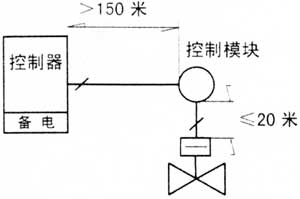

1. Cable: control cable 2*1.0 (the diameter of the cable can be increased accordingly if the transmissive control distance needs to be extended.)

2. Control Distance:

|

|

| |

|

|

|

| |

|

| |

| |

|

|

| |

If applying capacitor discharge drive: within 150m

If applying DC12V~24V direct current impulsing drive: within 300m

If applying this company¡¯s control module of valve terminal: the distance can reach 1500m

|

|

| |

|

|

|

| |

|

| |

| |

|

|

| |

If applying capacitor discharge drive: within 150m

If applying DC12V~24V direct current impulsing drive: within 300m

If applying this company¡¯s control module of valve terminal: the distance can reach 1500m

|

|

| |

|

|

|

| |

| ¡¡Explosion-proof Requirements |

|

| |

| |

|

|

| |

The distance between explosionproof junction box and the valve body should be less than 1m, and the construction work should be in accordance with the explosion-proof criteria.

|

|

| |

|

|

|

| |

| ¡¡Inspection after Installation |

|

| |

| |

|

|

| |

1.Manual Inspection: open the transparent protective cover and vertically draw the red reset handle upward or press it to see whether the switch works normally or not.

2.Inspect whether the connection with controller is right or wrong (white with positive and black with negative). The controller shall send out an instantaneous electrical signal of DC9-24V and the valve should be closed within one second.

3.If all the above are finished and normal , it can be put into usage.

|

|

| |

|

|

|

| |

|

| |

| |

|

|

| |

¡¤The opened valve can be shut off in two ways:

1.The valve will be shut off quickly when the electromagnetic coil is provided with a direct impulse (eg. DC12V/1s).

2.The valve can also be shut off by opening the protective cover and pressing the red handle manually.

¡ï Attention: Non-prefessionals are not allowed to open the protective cover for fear of incorrect operation.

¡¤When the valve is open:

For having been applied the principle of magnetic lock, the valve may be shut off automatically when encountering intense quake, which is normal. But if the self-locking force is too weak, the manufacturer should be informed for adjustment.

¡¤The closed valve can be opened in the only way:

Manual reset. That is: draw the red handle upward to open the valve.

¡ï Attention: If there are some difficulties in drawing up the handle, measures should be taken to minish the pressure difference between the valve¡¯s inlet and outlet. The less the difference is, the easier to open the valve. Please avoid violent operation by all means so as not to spoil the mechanism.

¡¤The valve, after emergently shut off, should be manually confirmed on the spot. The protective cover can be opened and aeration can be recovered through reset handle¡¯s opening the valve only if the hidden danger is eliminated.

¡¤Transparent protective cover, used to prevent incorrect operation and having the ability of dustproof and waterproof, can not be opened arbitrarily, to say nothing of damage or losses of it.

¡¤This product is shut off through instantaneous electrification drive, the time of continuous electrification should be no more than 30 seconds. Therefore, it is not allowed to be electrified for a long time, otherwise the performance will be seriously affected.

¡¤During the process of transportation, installation and usage, the product must not be watered or eroded by chemical inside and the coil cannot be close to strong magnetic field, otherwise the performance may be affected.

¡¤The rubber hermetical material inside of the product should be checked periodically and disposed by professionals¡¯ advice. It is suggested that it should be examined thoroughly every 5 years and replaced if necessary.

¡¤It is suggested that consumers should periodically inspect the product (the Emergency Shut-off Valve and the Controller) and inform professionals or manufacturers promptly of overhaul if there is any trouble.

|

|

| |

|

|

|

| |

|

| |

| |

|

|

| |

¡¤Any action of dismounting the valve may cause gas leak and the consequent accident.

¡¤If there is any trouble with the valve, maintainers should be informed promptly.

¡¤To maintain the valve, the gas source of the valve should be firstly cut off in front of the valve, meanwhile, shut off the valve so as to control the electrical supply.

¡¤It cannot be washed with water.

¡¤Please read relevant information carefully before installation and usage.

|

|

| |

|

|

|

| |